11 FAQs about Uni-Forge Hot Tap-Line Stop Fittings

Uni-Forge Hot Tap and Line Stop fittings are used in pipeline operations around the globe, built to the highest standards and supported by outstanding customer service. Here are some of the frequently asked questions related to our Hot Tap and Line Stop fittings to help you make the right decision for your business.

What is the largest fitting in terms of size and pressure class that Uni-Forge has made to date?

The largest fitting made to date is 42" x 42" x 2.25" wall thickness WPHY 70. Our standard size range varies between 2" – 48", however, we are equipped to provide larger sizes as needed.

At Uni-Forge, all products are designed and reviewed for compliance by expert staff members. We implement the following processes to control the quality of our product:

Raw material is selected to suit each apppcation and inspection for quapty assurance;

All of our fittings are designed to meet ASME & DOT piping code requirements and standards;

We use quapfied, in-house, welders and have certified WPS and PQRs covering our welding processes and materials;

Each component is thoroughly tested with relevant NDE processes;

All of our fittings come with a Quapty Assurance Data Package complete with material certificates, non-destructive test reports, heat treat reports and dimensional inspection reports.

What process does Uni-Forge follow to screen sub-vendors for raw material and services?

While Uni-Forge maintains an extensive stock of raw materials to reduce manufacturing lead times, we also maintain approved vendors per ISO 9001 which allow us to meet the most demanding lead times.

Which international codes are covered in the design of the fittings?

Uni-Forge fittings are designed to meet ASME B31.1, B31.3, B31.4, B31.8 code requirements as well as DOT standards.

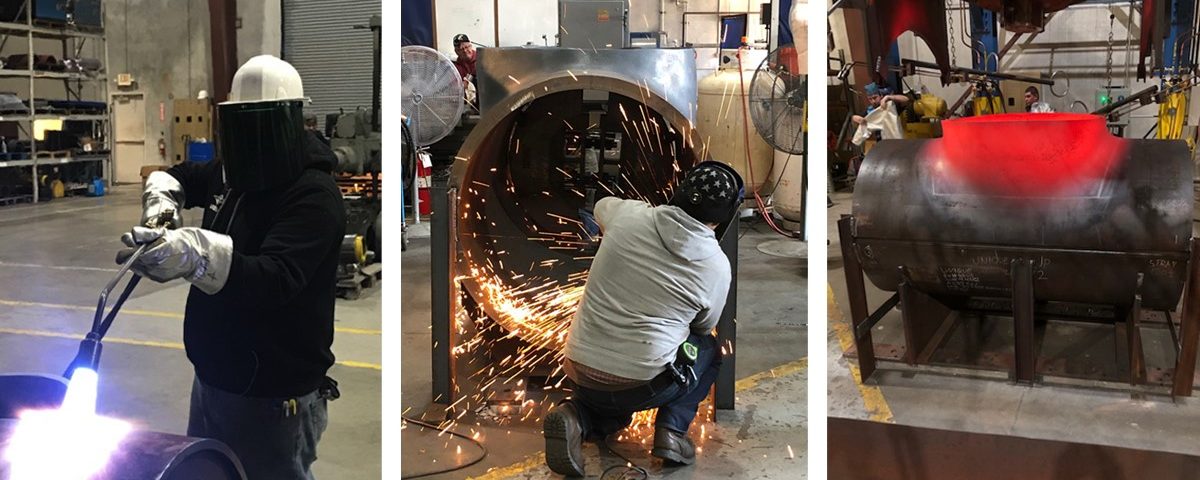

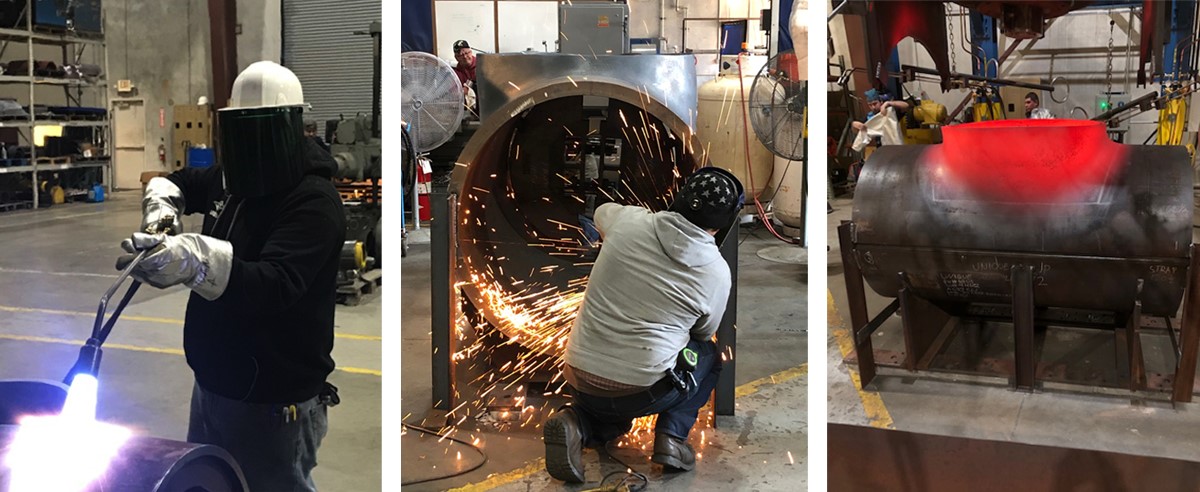

What is the primary manufacturing process followed by Uni-Forge?

Uni-Forge follows a safe, reliable and effective manufacturing process which involves forging, machining and welding.

What is the difference between Extruded and Fabricated fittings?

Fabricated fittings refer to a fabricated split tee and flange built in accordance with the customer's design requirements. Extruded fittings on the other hand, refer to a forged tee built to industry standards and customer requirements, a flange is added to produce the final product. The process of extrusion eliminates the stress risers in branches that are inherent in the welded type tees. The difficulty to radiograph this weld is also eliminated because of extrusion. Here, at Uni-Forge, our Hot Tap and Line Stop fittings are manufactured using both techniques, we can accommodate any need the customer may have.

What are the differences between a Hot Tap and a Line Stop fitting?

Uni-Forge Hot Tap fittings offer both full and reduced branch split tees and are designed for equipment tie-ins and line extensions with permanent full-bore valves. This means that a pipe can continue to be in operation while modifications are being done. Whereas, Uni-Forge Line Stop fittings are the ideal solution when operations call for the temporary or permanent stoppage of the pipeline. Line stoppage with bypass lines allow operators to isolate a section of the piping system in order to make repairs/alterations without interrupting line flow. Uni-Forge manufactures all related fittings for such operations.

Do all Hot Tap-Line Stop machines and equipment work with Uni-Forge fittings?

Uni-Forge fittings are compatible with all industry standard Hot Tap and Line Stop machines and equipment.

Using the following information, our technical experts will put together a custom quote to answer your needs:

Name and contact details

List of new fittings required (Hot Tap, Line Stop, Split Tee, Nozzle, etc.)

Details on existing pipeline (size, material, design pressure, operating pressure & temperature, etc.)

Specifications about new fittings (orientation, size, design code, material, etc.)

QA requirements

Uni-Forge Fitting Inquiry Forms are available for customer convenience. Contact us below.What market segments and industries does Uni-Forge cater to?

Uni-Forge caters to a diverse range of customers within the oil & gas industry, refining, petrochemical and pipeline transmission sectors.

What parts of the United States does Uni-Forge deliver to?

Uni-Forge ships to all parts of the United States and internationally.

If you prefer to contact us directly with your questions, we're always happy to help. Contact our team below or call us at +1 713 937 6193 for more information about Uni-Forge's Hot Tap and Line Stop fittings.

Topics: taptee, hottap, htls, hottapping, linestopping, extrusion