The Advantages of Extruded Hot Tap & Line Stop Fittings

Today's industrial safety culture depends on quality manufacturing of the products being used in the field. Extruded fittings offer your project optimum design flexibility, cost savings, and more. Every successful Hot Tap & Line Stop project begins with the fitting.

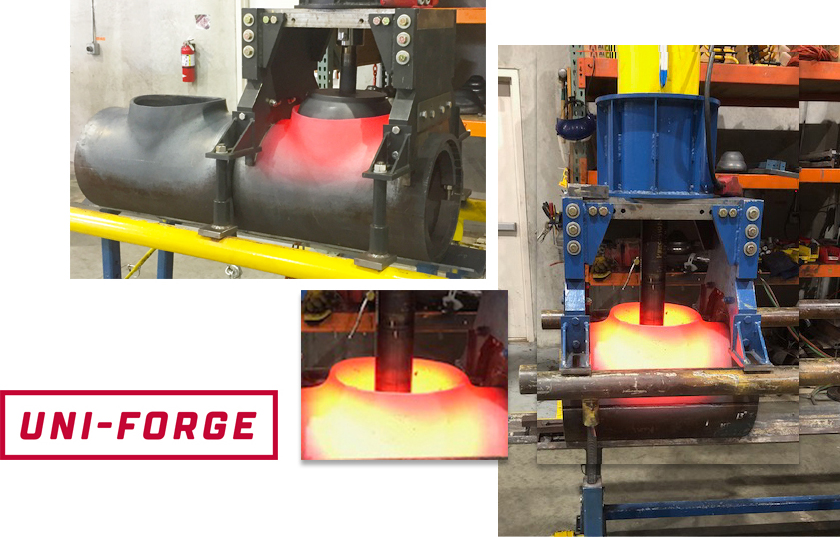

Understanding Steel Fitting Extrusion

Steel Fitting Extrusion can be accomplished in different ways. For example at Uni-Forge, steel cylinders are manufactured to a specific diameter, length and thickness. An engineered opening is cut into one side of the cylinder. The area of the extrusion is then heated sufficiently to allow the steel to form, yet not incur damage. A specially designed die is pulled through the side of the cylinder creating the outlet. Outlet dimensions have a wide range of standard sizes and can be customized to any requirement. Our team of engineers and craftsmen can design and produce any extruded branch required.

Safety Starts with Quality, Strength and Flexibility

Product Quality

What to look for:

Precise destructive and non-destructive raw material testing

Closed die extrusion process to ensure control of interior and exterior wall shape

Extruded outlets that enable 100% radiographic weld examination

An excellent surface finish

Superior Strength

What to look for:

An extrusion process that eliminates the stress risers in branches inherent in welded-type tees, making the weld easy to radiograph

Optimum Design Flexibility

What to look for:

Extruded headers offer design advantages that are unavailable with standard fittings

These headers maximize cost-savings and space requirements with a simple outlet configuration

Specifications to meet strict code requirements can easily be achieved

Girth welds between outlets are eliminated to reduce labor costs and inspection fees.

Know your vendor

When vetting your vendor, consider the following:

Years of experience in pipeline product manufacturing

Professional skills and state-of-the-art machinery necessary for high-quality manufacturing

Outstanding welding, machining and heat-treating capabilities

Proven ability to meet or exceed customer expectations for quality, price and lead time

Let's talk about your unique needs

Whether you have a complete design package or a conceptual idea, we at Uni-Forge have the experience, skills and equipment that meet your needs for quality and reliable pipe fittings. Contact us to find out how we can meet your branch outlet needs.

Topics: taptee, hottap, htls, hottapping, linestopping, extrusion