Hot Tapping 101: The Basics

Repairing damaged pipelines or adding branches to a current network doesn't have to require shutting down the full operation. This is where hot tapping comes into play.

On a basic level, hot tapping is the ability to safely tie into a pressurized system—by drilling or cutting—while the line is live. It's used when pipeline repairs are required due to damage or corrosion, or when adding branches to modify an existing network.

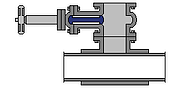

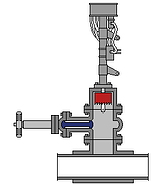

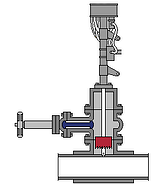

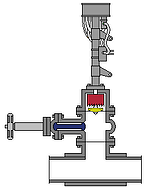

A typical hot tapping connection process consists of:

Isolation Valves

Closed die extrusion process to ensure control of interior and exterior wall shape

A hot tapping (HT) machine which includes the cutter and housing

The Six-step Hot Tapping Process

The Uptime Benefits of Hot Tapping

The hot tapping process can be performed on almost any type of pipe that carries fluid under pressure, ranging from carbon steel to PVC. Adding new connections to a pipeline is not the only reason for doing hot taps. Product sampling points, pressure control switch installations, inspections and draining pipes are just a few examples of hot tapping procedures. Not only is hot tapping cost efficient, but it is also a safe and effective way to keep facilities up and running during repairs and upgrades to vital infrastructure.

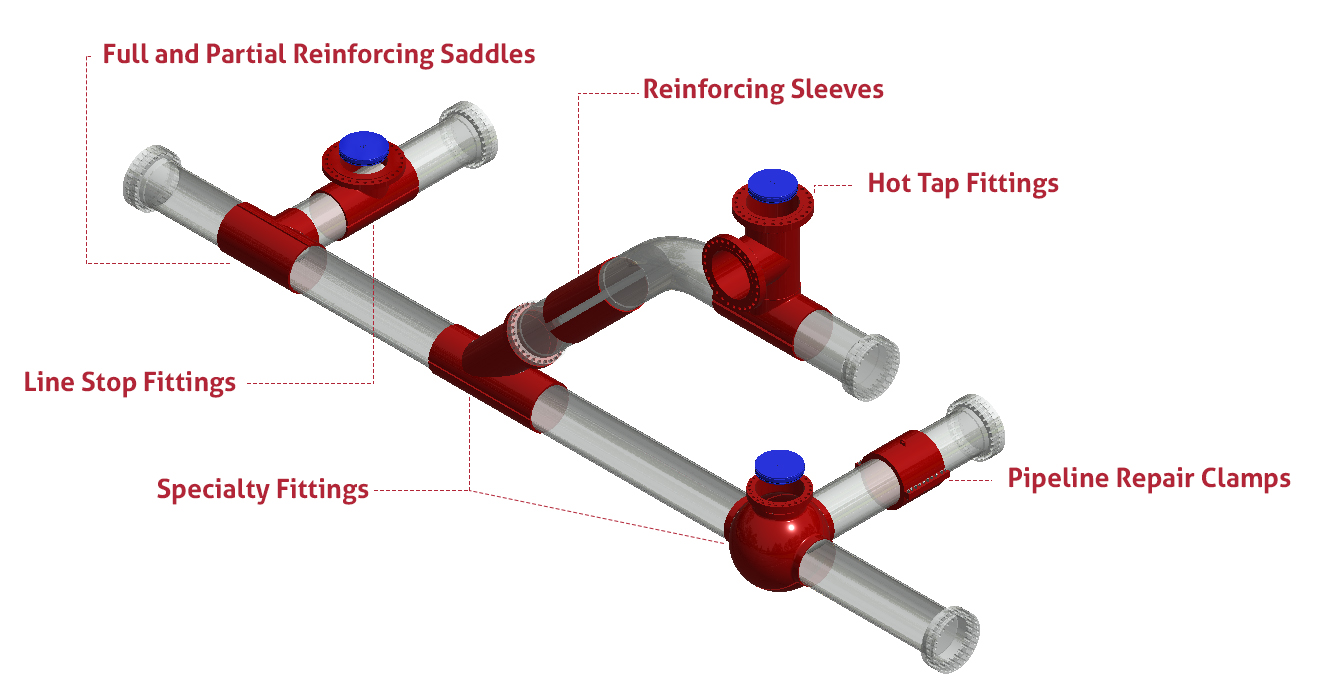

Trust a Quarter-century of Hot-tapping Expertise

Experience and Quality fittings are critical to the success of any successful hot tapping project. That's why customers worldwide trust Uni-Forge specialty fittings and pipeline reinforcement solutions. Manufactured in our own facilities, every fitting uses high-grade materials and our proven extrusion processes.

To learn more about the hot tapping process and the best options for quality pipe fittings, contact the Uni-Forge team,

Topics: taptee, hottap, htls, hottapping, linestopping,