Safe, effective and economical hot tap tees

When you need to work on a pressurized line, you need Uni-Forge Hot Tap fittings. Your safety, your employees’ safety, and pipeline integrity are our top priorities.

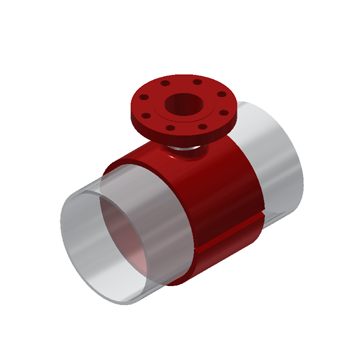

Our hot tap pipe fittings include full branch split tees designed for equipment tie-ins, lateral connections and line extensions using a permanent full-bore valve without shutdown.

Available in a wide range of sizes, from 2” to 48,” our fittings are equipped with a welding neck flange RF according to ANSI Class 150, 300, 600 or 900. Larger sizes and pressure ratings are available to meet any need.

With personalized customer service and a commitment to on-time delivery, you can trust all your hot tap tee needs to Uni-Forge.

Uni-Forge fittings are available with a reducing branch to connect pipelines of varying sizes.

Uni-Forge Hot Tap Tee Fittings:

- Coded for material identification and traceability

- Provided with material certificates

- Manufactured and delivered to your quality control specifications

If required, Uni-Forge can perform:*

- Ultrasonic Testing (UT)

- Liquid Penetrant Testing (PT)

- Radiographic Testing (RT)

- Magnetic Particle Inspection (MPI)

- Product Analysis (Chemistry Check)

- Hydrogen Induced Cracking (HIC)

- Sulfide Stress Cracking (SSC)

- Full Body Hydrotesting

*Uni-Forge will perform relevant tests as specified by code or as requested by customer..

Based on pipeline size and specifications, the hot tap fitting can be provided with a different reinforcement such as a weldolet or pad.

Technical Specifications

| Size Range | 2" to 48" - larger sizes available |

| Pressure Rating | 150# - 900# |

| Wall Thickness | Up to 4" depending on the size |

| Material | Carbon steel, Alloy steel, and Stainless steel |

| Codes | ASME B31.1, B31.3, B31.4, B31.8 and DOT compliant |

| Flange Type | Standard ASTM A105 flanges to ASME B16.5/ 16.47 |

| Uni-Lock Flange™ can be provided for installation of pigging bars |