Strength. Adaptability. Reliability.

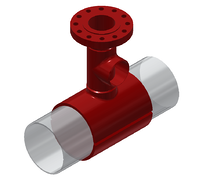

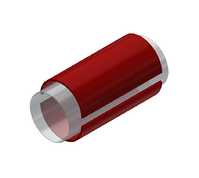

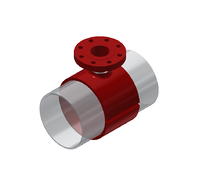

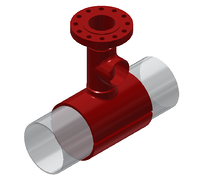

The Uni-Seal Split Sleeve Repair Clamp is designed to allow temporary repairs to damaged pipelines by producing a high integrity seal around the damaged area of the pipe. Uni-Seal SSRCs are designed using the latest technology, allowing optimization of design techniques and materials, resulting in lower weight, reduced bending tendencies, and a more economical product.

Rely on us to meet tight deadlines.

By keeping Uni-Seal Clamps in stock we can significantly reduce manufacturing lead times—ensuring you have the product you need—right when you need it..

Uni-Custom-built quality you can count on.

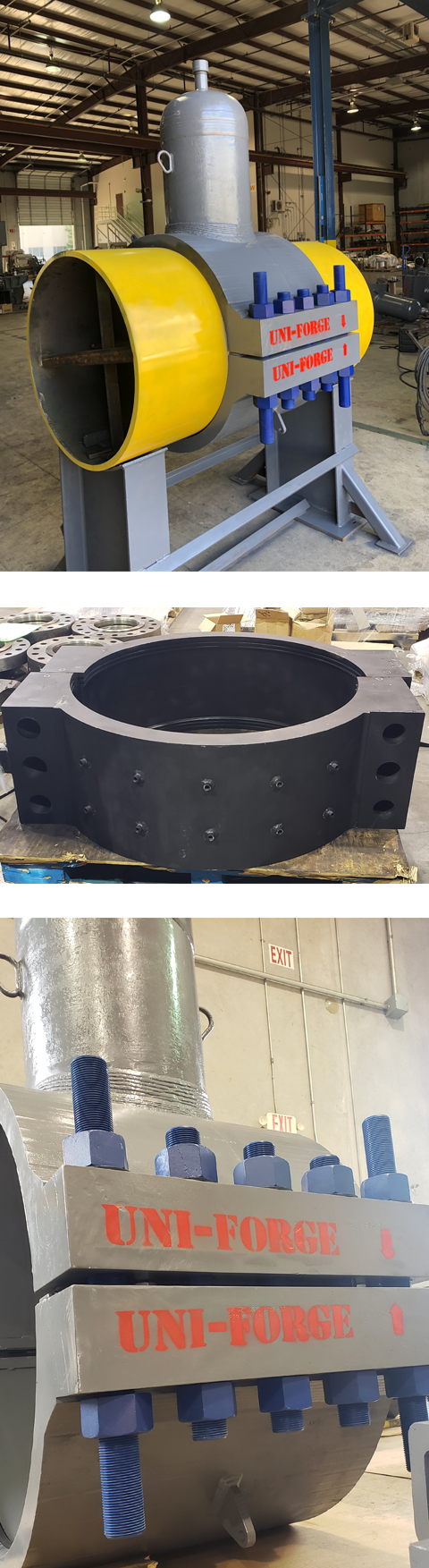

Uni-Forge Uni-Seal Clamps are the ideal solution when pipeline repair is needed and are designed to be installed with the most common tools available.

We offer our clients personalized customer service according to their project needs, manufactured to high specifications, including the Uni-Seal specialty clamp with illegal tap dome.

Material Specifications:

- Shell:

ASTM A105, A106, A516, A216 - Stud Side Bars:

ASTM A105, A516, A216 Gr. - Coating:

Body shell receives a red oxide primer coating. For subsea applications, a white or yellow marine epoxy coating is applied.- PTFE Coated Fasteners:

- Studs: ASTM A193 B7

- Nuts: ASTM A194 2H

- Seals:

Single die moulded or slit nitrile rubber typically Buna-N or Viton. Other sealing material provided on request. - Anodes:

Sacrificial anodes are fitted on all sub-sea clamps.

Why Uni-Forge has been the right choice for over 25 years.

- Personalized customer service and a commitment to on-time delivery

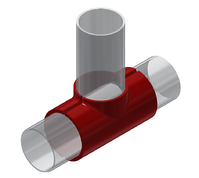

- Fittings are manufactured with extruded outlets, eliminating stress risers in branches that are inherent in welded-type tees. Extrusion also eliminates difficulties when radiographing the weld

- All products come with a Quality Assurance Data Package complete with material certificates, non-destructive test reports, heat treat reports and dimensional inspection reports, and are designed to meet ASME piping code requirements and DOT standards

- Hot tap and line stop fittings are provided with ASME Class 150 to 900 flanges with options of Raised Face or RTJ grooves

- All fittings are compatible with all industry standard Hot Tap and Line Stop equipment

- We use qualified, in-house, third party approved welders and have WPS and PQRs covering most common welding processes and materials