Rely on us to meet tight deadlines.

With extensive raw material in stock, including common size-on-size full-bore tees in semi-finished conditions, we can significantly reduce manufacturing lead times—ensuring you have the product you need—right when you need it..

Custom-built quality you can count on.

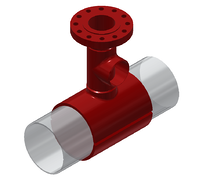

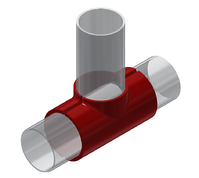

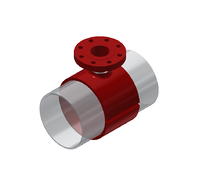

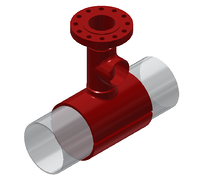

Uni-Forge Line Stop fittings are the ideal solution when pipeline repair or maintenance is needed. Our Line Stop fittings are designed to be safe for virtually any distribution pipeline, including oil, natural gas, and others. We offer our clients personalized customer service according to their project needs.

Our fittings are engineered and extruded with outlets from 2" to 48," and equipped with Uni-Lock Flange™ closures rated to ANSI class 150, 300, 600 or 900. Larger sizes and pressure ratings are available.

Fittings are also:

- Coded for material identification and traceability

- Provided with material certificates

- Manufactured and delivered to your quality control specifications

If required, Uni-Forge can perform:*

|

|

|

|

|

|

|

|

*Uni-Forge will perform relevant tests as specified by code or as requested by customer.

Technical Specifications

| Size Range | 2" to 48" - larger sizes available |

| Pressure Rating | 150# - 900# |

| Wall Thickness | Up to 4" depending on the size |

| Material | Carbon steel, Alloy steel, and Stainless steel |

| Codes | ASME B31.1, B31.3, B31.4, B31.8 and DOT compliant |

| Flange Type | Uni-Lock Flange™ with completion plug, with or without scarfed nipple facilities. |

Why Uni-Forge has been the right choice for over 25 years.

- Personalized customer service and a commitment to on-time delivery

- Fittings are manufactured with extruded outlets, eliminating stress risers in branches that are inherent in welded-type tees. Extrusion also eliminates difficulties when radiographing the weld

- All products come with a Quality Assurance Data Package complete with material certificates, non-destructive test reports, heat treat reports and dimensional inspection reports, and are designed to meet ASME piping code requirements and DOT standards

- Hot tap and line stop fittings are provided with ASME Class 150 to 900 flanges with options of Raised Face or RTJ grooves

- All fittings are compatible with all industry standard Hot Tap and Line Stop equipment

- We use qualified, in-house, third party approved welders and have WPS and PQRs covering most common welding processes and materials