Rely on us to meet tight deadlines.

With extensive raw material in stock, including common size-on-size full-bore tees in semi-finished conditions, we can significantly reduce manufacturing lead times—ensuring you have the product you need—right when you need it..

Custom-built quality you can count on.

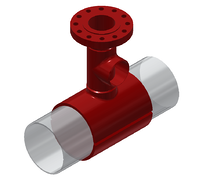

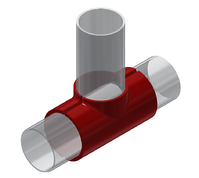

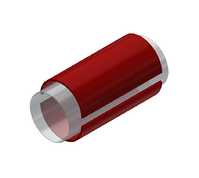

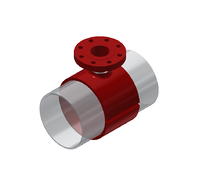

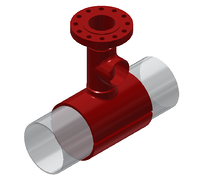

Uni-Forge hot tap fittings are designed for equipment tie-ins and line extensions with permanent full-bore valves. Available in sizes from 2″ to 48,″ fittings are equipped with a weld neck flange RF according to ANSI Class 150, 300, 600 or 900, with larger sizes and pressure ratings available.

Each manufactured Uni-Forge fitting comes with a Mill Test Report (MTR) package tailored to your specific requirements. Our level of Non-Destructive Evaluation (NDE) includes all design code required testing.

Uni-Forge will perform any of the following tests as requested:

- Ultrasonic Testing (UT)

- Liquid Penetrant Testing (PT)

- Radiographic Testing (RT)

- Magnetic Particle Inspection (MPI)

- Product Analysis (Chemical Check)

- Hydrogen Induced Cracking (HIC)

- Sulfide Stress Cracking (SSC)

- Full Body Hydrotesting

Based on pipeline size and specifications, Uni-Forge fittings can be provided with different reinforcements such as a weldolet or re-pad.

Why Uni-Forge has been the right choice for over 25 years.

- Personalized customer service and a commitment to on-time delivery

- Fittings are manufactured with extruded outlets, eliminating stress risers in branches that are inherent in welded-type tees. Extrusion also eliminates difficulties when radiographing the weld

- All products come with a Quality Assurance Data Package complete with material certificates, non-destructive test reports, heat treat reports and dimensional inspection reports, and are designed to meet ASME piping code requirements and DOT standards

- Hot tap and line stop fittings are provided with ASME Class 150 to 900 flanges with options of Raised Face or RTJ grooves

- All fittings are compatible with all industry standard Hot Tap and Line Stop equipment

- We use qualified, in-house, third party approved welders and have WPS and PQRs covering most common welding processes and materials

| Size Range | 2" to 48" - larger sizes available |

| Pressure Rating | 150# - 900# |

| Wall Thickness | Up to 4" depending on the size |

| Material | Carbon steel, Alloy steel, and Stainless steel |

| Codes | ASME B31.1, B31.3, B31.4, B31.8 and DOT compliant |

| Flange Type | Standard ASTM A105 flanges to ASME B16.5/ 16.47 |